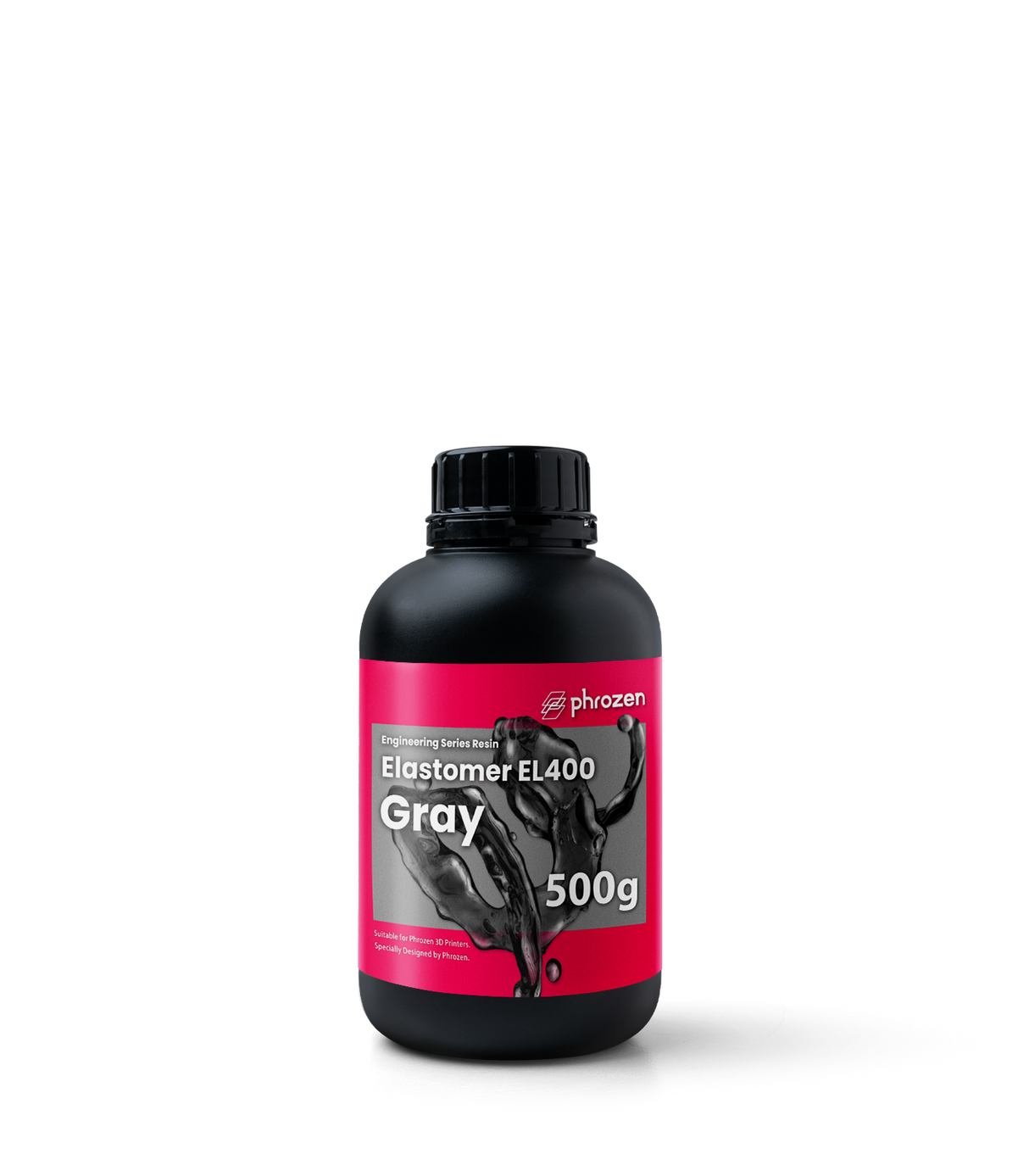

Phrozen Engineering Elastomer EL400 Resin

Couldn't load pickup availability

Shipping & Tariff

-

Now Available Countries: France, Germany, Italy, Spain, Poland, Czech Republic, Netherlands, Slovakia, Bulgaria, Croatia, Cyprus, Denmark, Estonia, Finland, Greece, Hungary, Ireland, Latvia, Lithuania, Luxembourg, Malta, Portugal, Romania, Slovenia, and Sweden.

- In some countries, an import license is required. Click here for details.

- The purchase price excludes tariffs and shipping costs. No refunds will be provided if a customer refuses to collect or returns their product(s) due to customs fees, duties, or other related costs.

- Customers are responsible for customs clearance in all countries.

- Shipping costs vary by country; see our check-out page for details.

- For more information, please refer to our Shipping Policy page.

Shipping Notice: In-stock items are prioritized and arranged to ship first. Out-of-stock items will ship once available.

Return & Warranty

- According to the Consumer Protection Act, you have the option to request a refund within a period of 13 days. However, please note that the refund does not cover the shipping fees and tax/VAT charges. To initiate the refund process, you need to submit a request to the Phrozen Support Center within this 13-day timeframe. It is important to ensure that the product is returned in its original condition, and the entire batch order must be sent back. For more details, please refer to our Refund Policy page.

-

All products purchased from the official website of Phrozen are warranted under different terms. Phrozen offers a one-year warranty for all our products except consumables and components; this includes the LCD screen and the FEP film. LCD screens for the Sonic Mighty 8K, Sonic Mini 8K, Sonic Mega 8K, Sonic Mini 4K, and Sonic 4K are covered under a 3-month warranty. For more details, please refer to our Warranty page.

*Kind reminder: We would suggest pairing our printers with Phrozen's resins to prevent surface paint damage. If a problem occurs, please feel free to contact our support team.

Precautions

Precautions

Resources

Resources

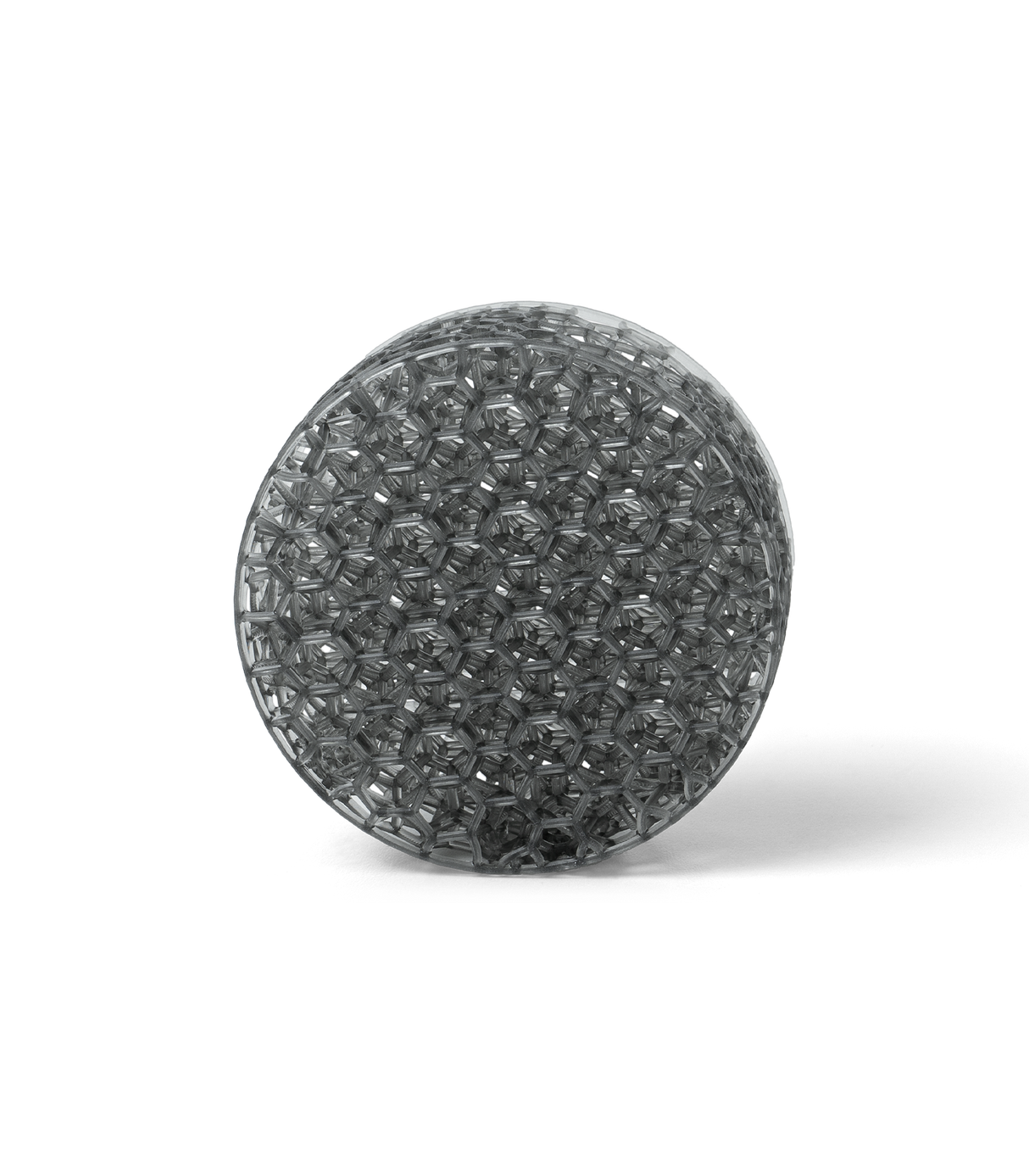

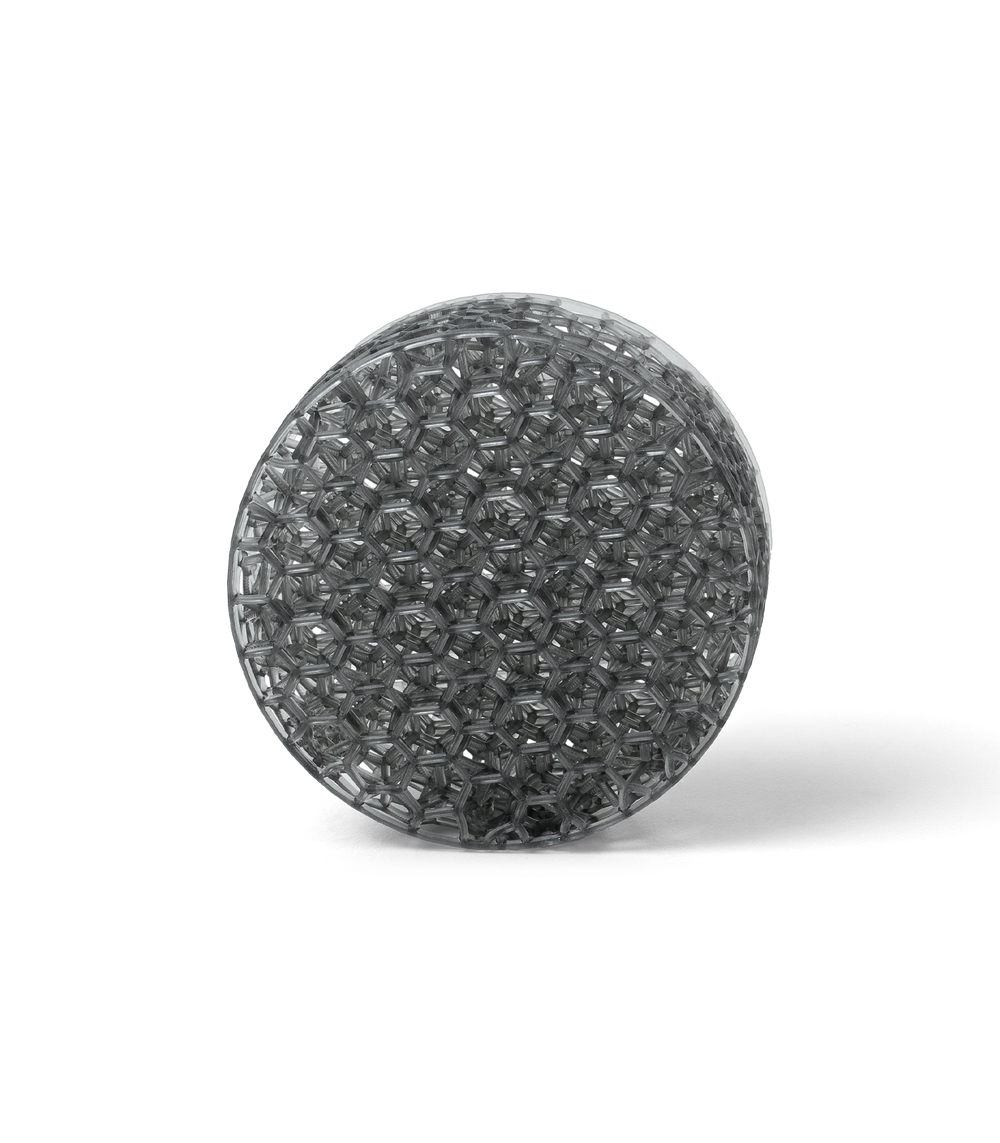

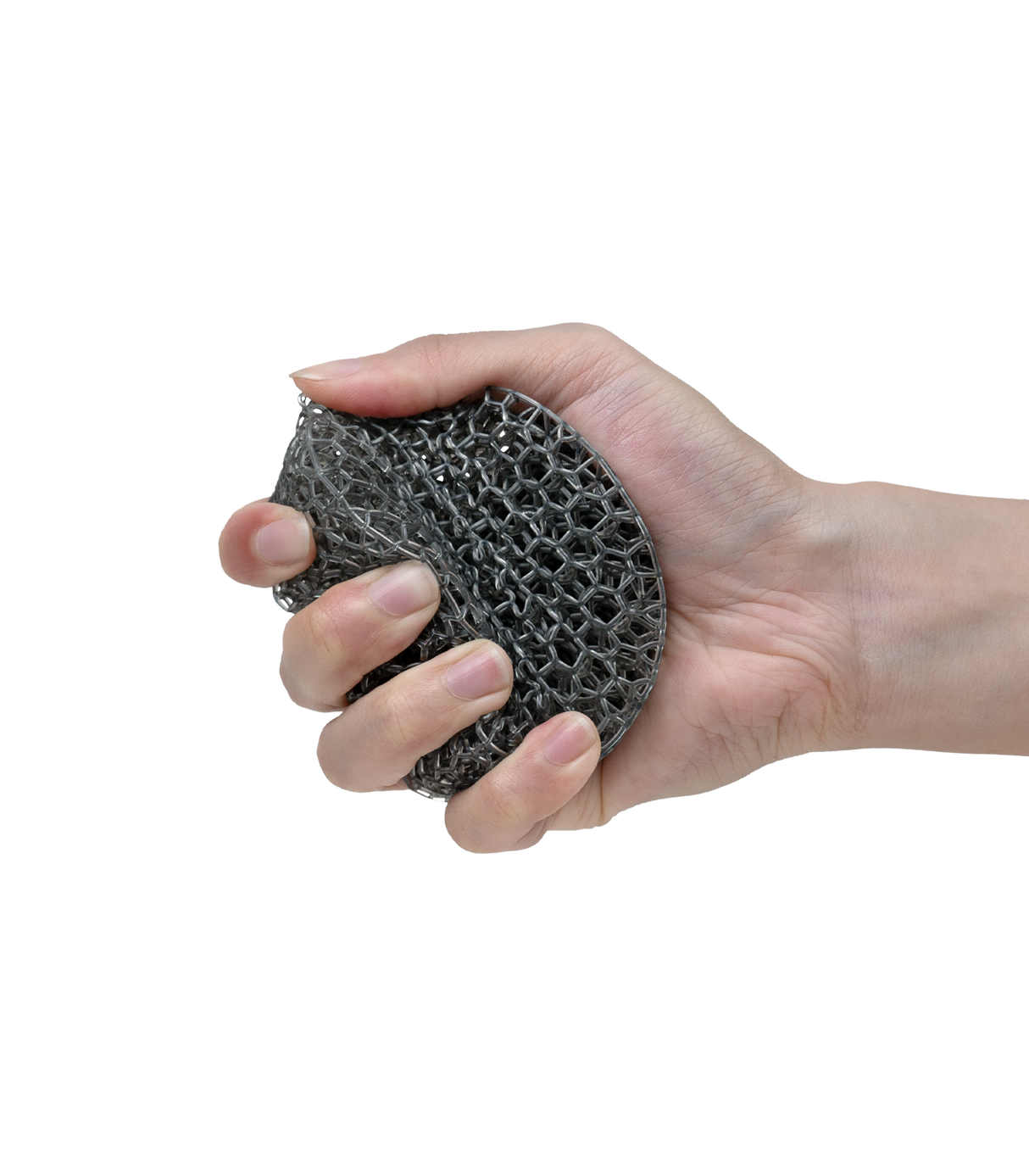

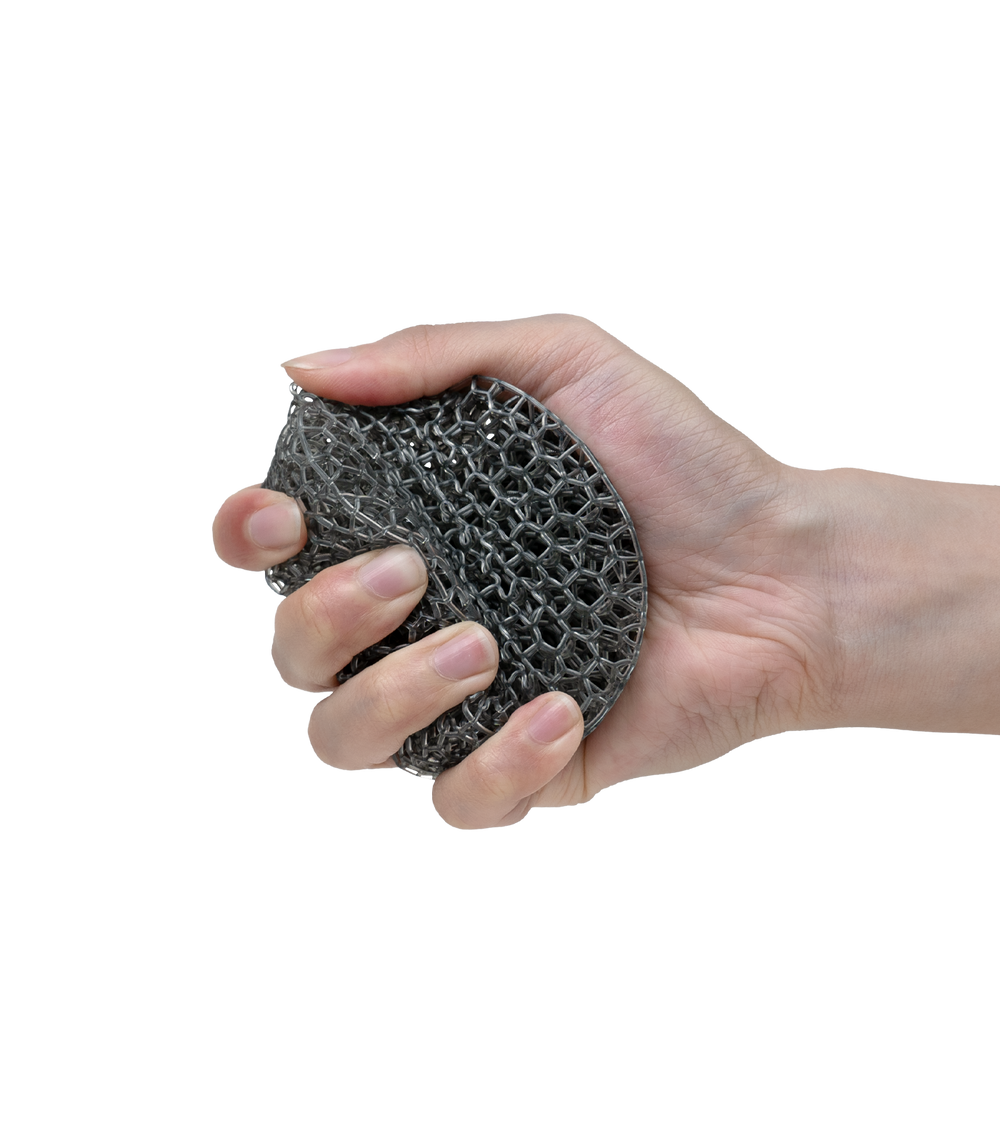

Ultra-High Elasticity

Excellent Resilience and Reboundability